torsion test instron|metal torsion testing : service The Instron 8850 series system is a floor model biaxial servohydraulic dynamic test system that provides axial and torsional load on a specimen in an integrated biaxial actuator. Resultado da Torinha__s (Vitória stefany) pictures and videos on EroMe. The album about Torinha__s (Vitória stefany) is to be seen for free on EroMe shared by .

{plog:ftitle_list}

Resultado da Dados meteorológicos fornecidos por. Previsão do tempo Tramandaí para 10 dias - Rio Grande do Sul - ClimaTempo.com. Informer; Contacts

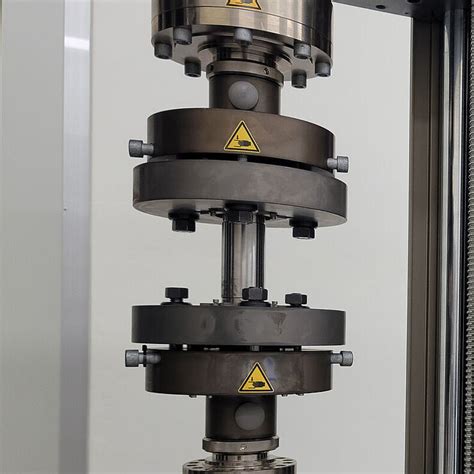

Instron offers stand-alone torsion testing systems available in capacities ranging from 22 - 5,650 N-m (200 - 50,000 in lb), a torsion add-on for universal testing systems, and biaxial testing systems for dynamic and fatigue testing.Packaged with Instron high-performance control electronics, the MT Series provides highly accurate test data and control for testing wire, fasteners, metal components, switches, and . Designed primarily for low-capacity (450 µNm - 225 Nm) torsion testing of materials and components, the MT torsion testing systems offer accurate, multi-turn .Packaged with Instron high-performance control electronics, the MT Series provides highly accurate test data and control for testing a product portfolio that includes wire, fasteners, switches, and springs used in the biomedical, .

The Instron 8850 series system is a floor model biaxial servohydraulic dynamic test system that provides axial and torsional load on a specimen in an integrated biaxial actuator.

Low-Capacity Torsion Testing Systems. Features and Benefits. Dual linear slide design offers high-torsional stiffness and low-axial friction. Tabletop system requires minimal lab space. .The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed. These are used as damping elements in two-mass flywheels of modern clutch systems.

The preferred solution for low-force torsion testing and component in-service simulation, the MT MicroTorsion systems are available in two standard models with force capacities up to 225 N .The Instron® Torsion Add-On 2.0 for Electromechanical Universal Testing Systems is designed for simple, simultaneous axial and torsional testing of devices and/or components, but has the .

what is torsional testing

Torsion Testing Equipment. Torsion testing can be performed on any one of several different testing systems depending on the specific application. Some labs prefer a dedicated torsion-only testing system such as Instron's MT MicroTorsion Series, while others may prefer to adapt their existing universal testing machine with a Torsion Add-On 3.0 fixture that enables the system .To meet the challenges of axial-torsion testing, Instron provides a range of axial-torsion machines that cover small implants made of compliant biomaterials, composites and high-performance metals and alloys. Our servohydraulic range provides mid to high axial and torque capacities, while the ElectroPuls biaxial variants complete the range with .This test is best performed on a torsion testing system such as Instron's MT Series with Bluehill Universal software. Gripping solutions depend on the diameter and hardness of the material, and can range from collet grips for .

The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed. These are used as damping elements in two-mass flywheels of modern clutch systems. . Subscribe to Instron News! Check this box to receive pertinent commercial email from Instron focusing on products, upcoming .

Controller and Software. The Instron 8850 series is supplied with a two-axis 8800MT digital controller, which comes with Console software to provide full system control from the PC, including waveform generation in both axes, calibration, limit set up, and status monitoring.The 8800MT controller also enables the use of WaveMatrix3 block loading software for simple and .

To meet the challenges of axial-torsion testing, Instron provides a range of axial-torsion machines that cover small implants made of compliant biomaterials, composites and high-performance metals and alloys. Our servohydraulic range provides mid to high axial and torque capacities, while the ElectroPuls biaxial variants complete the range with .The axial annexes of ASTM F543 can be performed on a static universal testing system such as Instron's 6800 Series, while the torsional annexes can be performed on a torsion-only system such as Instron's MT Torsion Series. The recent introduction of the Torsion Add-On 3.0 allows both axial and torsional testing to now be performed on a single 6800 Series system.The ElectroPuls® E10000 Linear-Torsion is a state-of-the-art, all-electric test instrument designed for dynamic and static testing on a wide range of materials and components. It includes Instron® advanced digital control electronics, bi-axial Dynacell™ load cell, Console software, and the very latest in testingTorsion Testing Equipment. Torsion testing can be performed on any one of several different testing systems depending on the specific application. Some labs prefer a dedicated torsion-only testing system such as Instron's MT MicroTorsion Series, while others may prefer to adapt their existing universal testing machine with a Torsion Add-On 3.0 fixture that enables the system .

The preferred solution for low-force torsion testing and component in-service simulation, the MT MicroTorsion systems are available in two standard . Packaged with Instron high-performance control electronics, the MT Series provides highly accurate test data and control for testing a product portfolio that includes wire, fasteners, switches, .The dynamic torsion test stand is designed for the operational fatigue testing of torsional vibration dampers under rotational speed. These are used as damping elements in two-mass flywheels of modern clutch systems. . Subscribe to Instron News! Check this box to receive pertinent commercial email from Instron focusing on products, upcoming .Our Solution. Instron ® MT Series systems offer a range of capacities for torsion testing ideal for testing drive shafts. These systems offer accurate, multi-turn capability with high torsional stiffness. Adjustable horizontal test openings and lathe .Torsion Testing Equipment. Torsion testing can be performed on any one of several different testing systems depending on the specific application. Some labs prefer a dedicated torsion-only testing system such as Instron's MT MicroTorsion Series, while others may prefer to adapt their existing universal testing machine with a Torsion Add-On 3.0 fixture that enables the system .

The 6800 Series universal testing systems are powered by Instron’s Bluehill Universal software. Equipped with easy-to-understand icons and workflows, Bluehill Universal makes it simple to train users and set up tests, helping you maximize lab efficiency while minimizing costly errors. . The Torsion Add-On easily mounts to any new or .Our Solution. The Torsion Add-On 3.0 is capable of twisting FPC panels at various degrees of rotation, while pneumatic side action tensile grips can be used to hold FPC panels in the correct position for performing the twisting .Torsion Testers. Dynamic and Fatigue Testing Systems. Rheometers & Melt Flow Testers. Impact Drop Towers & Pendulums. HDT & Vicat . As a global leader in materials testing, Instron is working closely with industry leaders to .Torsion Testers. Dynamic and Fatigue Testing Systems. Rheometers & Melt Flow Testers. Impact Drop Towers & Pendulums. HDT & Vicat. . Test Setup and Method Development. Instron’s new 6800 Series systems are ideal for simple .

Our Solution. Instron ® MT Series systems offer a range of capacities for torsion testing ideal for testing drive shafts. These systems offer accurate, multi-turn capability with high torsional stiffness. Adjustable horizontal test openings and lathe .

The MT Series torsion testing systems are available in six standard models with force capacities ranging up to 5,650 N-m (50,000 lbf-in) and are used for torsion testing and component in-service simulation. . Packaged with Instron high-performance control electronics, the MT Series provides highly accurate test data and control for testing .

Materials testing systems are potentially hazardous. Materials testing involves inherent hazard s from high forces, rapid motions, and stored energy. You must be aware of all moving and operating components in . Product Support: www.instron.com Refer to “Torsion controller assembly” on . 3.The MT Series torsion testing systems are available in six standard models with force capacities ranging up to 5,650 N-m (50,000 lbf-in) and are used for torsion testing and component in-service simulation. . Packaged with Instron high-performance control electronics, the MT Series provides highly accurate test data and control for testing .Instron offers a range of t-slot tables and component test plates for both single and dual column test frames for clamping and fixturing difficult to grip components. In addition to this, manual screw side action grips are ideal to use because the grip face can be offset in order to keep forces within the center of the load string.

Preventative maintenance helps you get the most out of your test system, and combining preventative maintenance with calibration services is the most convenient and economical way for you to meet ISO 9001, ASTM E4, and ASTM E83 compliance requirements.. Instron's engineers have access to the documentation, factory-specified parts, and tools required to maintain your .Torsion cells for use with the 55MT series torsion frames are available in several capacities depending on the frame model. Lower capacity cells extend the range of the machine and increase the functionality of the 55MT Series test frame. For the 55MT1, the torsion cells are miniature reaction torque transducers.

To meet the challenges of axial-torsion testing, Instron provides a range of axial-torsion machines that cover small implants made of compliant biomaterials, composites and high-performance metals and alloys. Our servohydraulic range provides mid to high axial and torque capacities, while the ElectroPuls biaxial variants complete the range with .Axial Torsion Testing_POD_EN_V2 www.instron.com Worldwide Headquarters 825 University Ave, Norwood, MA 02062-2643, USA Tel: +1 800 564 8378 or +1 781 575 5000 European Headquarters Coronation Road, High Wycombe, Bucks HP12 3SY, UK Tel: +44 1494 464646 AXIAL-TORSION TESTINGThis test is best performed on a torsion testing system such as Instron's MT Series with Bluehill Universal software. Gripping solutions depend on the diameter and hardness of the material, and can range from collet grips for softer materials to chucks for harder materials. The jaw faces are recommended to have a hardness greater than 55 HRC.

tear test for dry eyes

tear test for paper

WEBBuy The Closer - Season 5, Episode 12 on Vudu, Amazon Prime Video, Apple TV. A woman is stabbed to death by someone wearing a ninja outfit; a detective arrives from El .

torsion test instron|metal torsion testing